Certification of Quality

We received Certification of Quality for our Heat Treatment Process from Sumitomo (S.H.I.) Construction Machinery Company Limited in February, 2014.

adopting both JIS and national JB or JB/T standards with strong focus on stringent quality assurance

We received Certification of Quality for our Heat Treatment Process from Sumitomo (S.H.I.) Construction Machinery Company Limited in February, 2014.

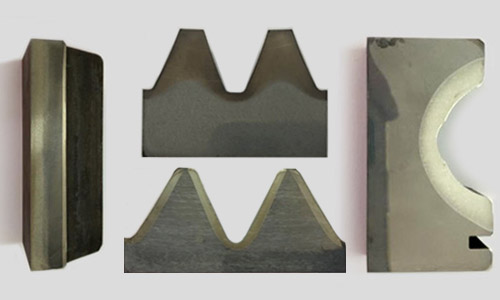

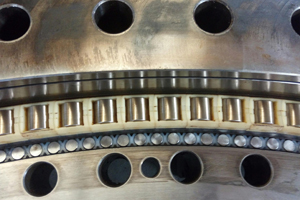

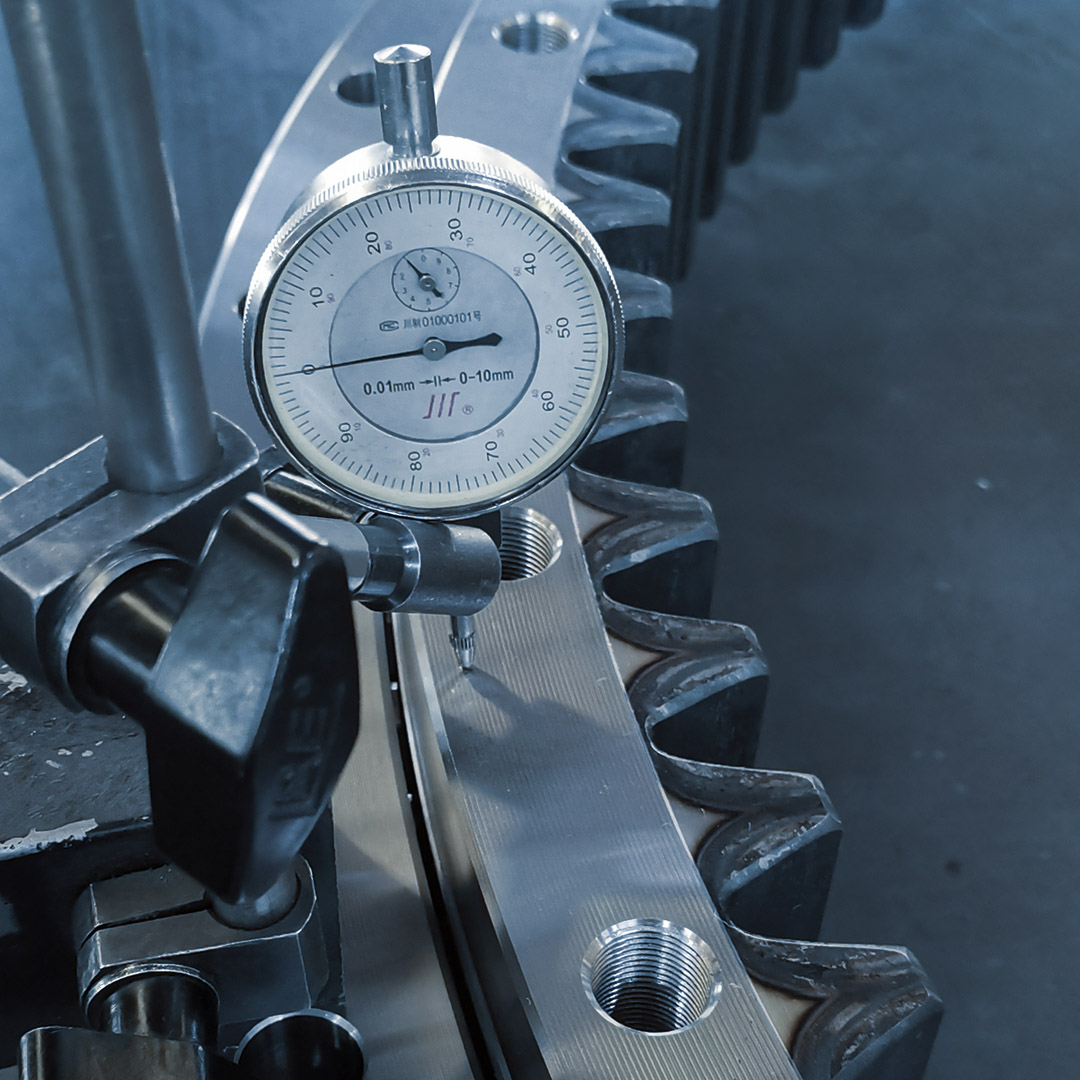

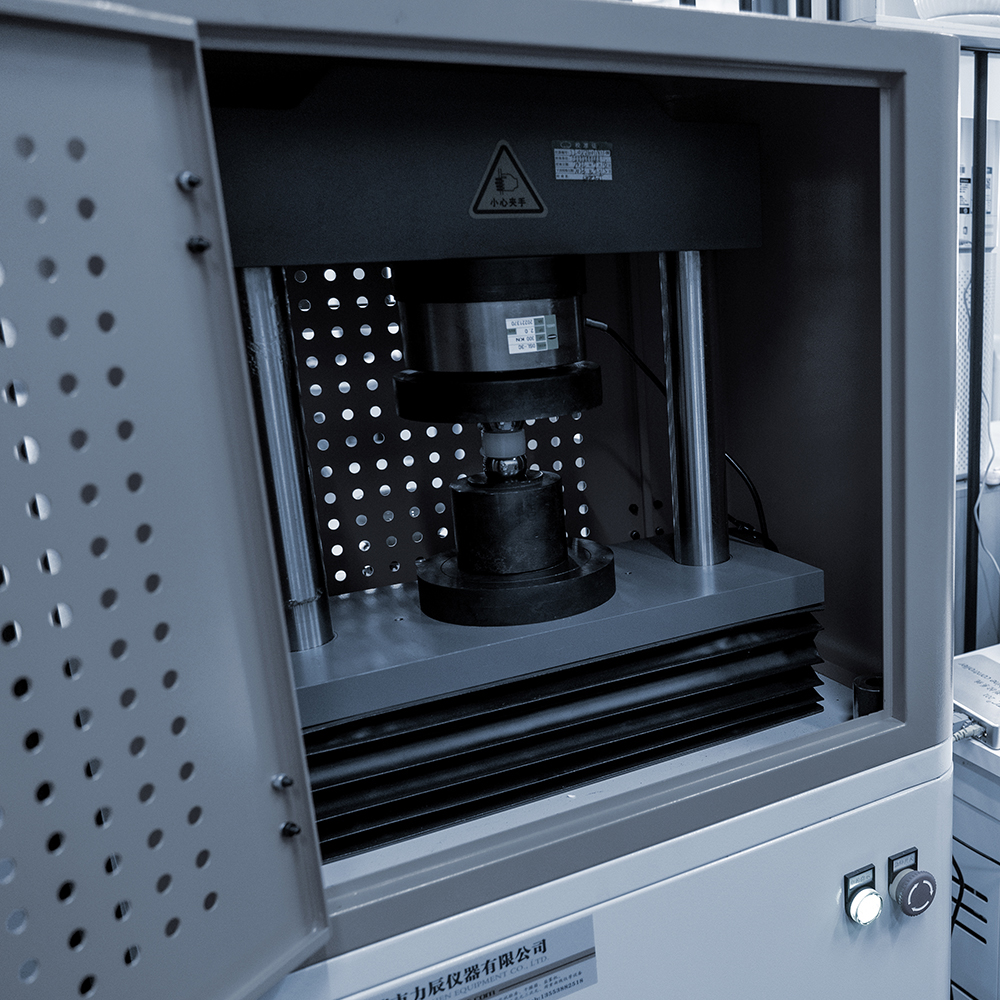

In order to ensure that our heat treatment is carried out properly and up to the standard required by our customers, we take samples from the finished products for tests and dissect them to perform various tests on their precision and accuracy and other quality requirements. We check whether the heat treatment is done properly for the entire work-in-progress and the average passing rate was approximately 99%. In the case of any product return or complaint, we will carry out various test to identify the origin of the problem to ensure out quality assurance standard. We hold regular meetings to discuss our quality assurance procedure and improve it from time to time.

We inspect the magnetic particle on a random sampling basis to check if the forgings have inner defect.

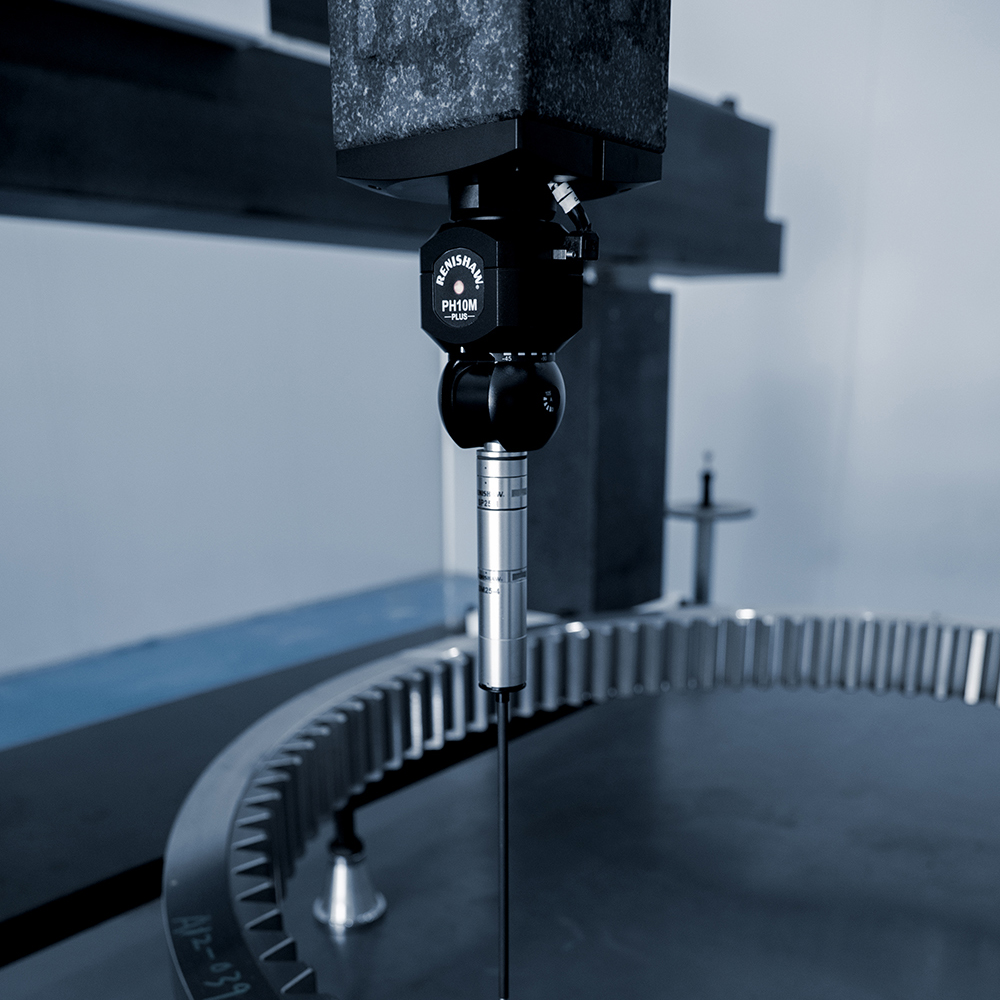

Upon passing our internal control check, we attach an identification tag to the forged ring to record the passing of the quality assurance check. Our inspection team and measurement team conduct quality assurance tests at each stage of the production process. We conduct physical inspection by deploying measurements tools and magnetic particles inspection tools. The objective is to ensure that the products will meet the quality, and identify any defect in the production process.

It indicates the standards used for industrial activities in Japan. Japanese Industrial Standards Committee (JISC) coordinates the standardisation process and publishes through the Japanese Standards Association (JSA)

“JB” or “JB/T” recommend industry standards

issued by the MIIT (Ministry of Industry and Information Technology ) in Machinery Making Industry